Description

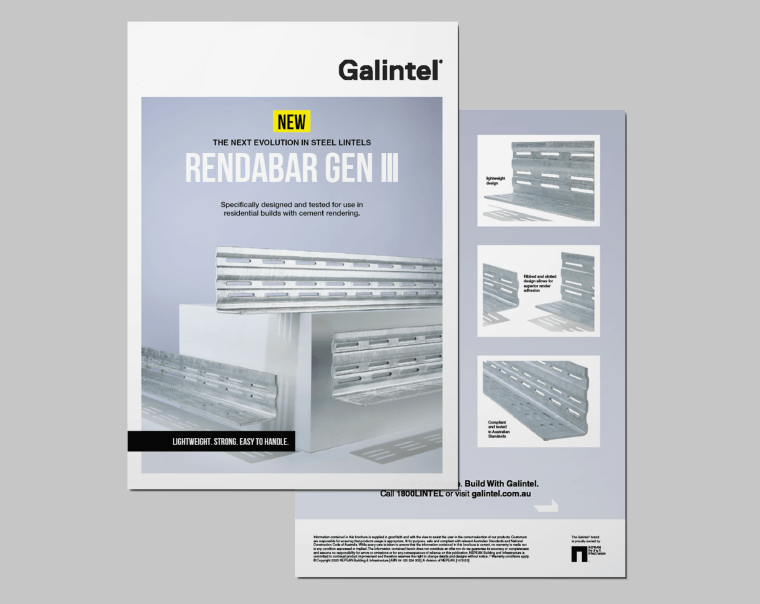

Galintel Rendabar Gen III is specifically designed for lintel applications with cement rendering. With its specialised design the bond between mortar, brick and lintel creates superior strength and structural integrity.

Features:

- Slotted design to support brickwork over openings where a rendered finish is required.

- Gen III design provides maximum adhesion with the introduction of slits on the horizontal and vertical of the lintel creating an excellent mechanical bond for the render.

- New heel profile design makes it easier for brick installation.

- Fully Hot-Dip Galvanised to AS/NZS4680.

- Achieves R3 Durability Rating to AS/NZS2699.3.

- Compliant with relevant Australian Building Codes & Australian Standards.

- Australian designed and manufactured.

- Full product warranty.

- Stamped.

- Labelled & bar coded.

Benefits:

- Superior performance

- Long life and durability

- Easy identification

- Peace of mind

Size & Stock Length Guide:

100 m (v) x 100 mm (b) x 6 mm (7.8kg/mtr) | 150 mm (v) x 100 mm (b) x 6 mm (10.26kg/mtr) |

|---|---|

900 | 1800 |

1200 | 2100 |

1500 | 2400 |

1800 | 2700 |

2100 | 3000 |

2400 | 3300 |

3600 | |

4000 |

v = (vertical leg)

b = (base leg)

Have a Question?

FAQs

FOR OVER 30 YEARS THE AUSTRALIAN CONSTRUCTION INDUSTRY HAS RELIED ON GALINTEL® GALVANISED STEEL LINTELS AS THE BRAND WHICH GUARANTEES STRONGER, MORE DURABLE AND SAFER LINTELS.

The previous Galintel® Rendabar represented a pioneering design that, for the very first time, allowed builders to render directly over a steel lintel without any additional treatment. While it was a hugely successful and trouble-free design, we are constantly striving to improve product performance. After extensive R&D and industry consultation, our team has developed a superior product with improved render adherence than the previous generation, while optimizing our Coffs Harbour plant manufacturing processes to introduce a new cost effective solution for this application.

The new design utilises the trusted profile of the Galintel® Solid Base Angle, which has been the lintel of choice for builders for decades and is time-tested for reliability. Specifically, Rendabar Generation III features a ribbed design with new, unique offset slots. The ribs are identical in shape and position to the Solid Base Angle, adding strength to the new design while making installation uniform across the lintel range. The offset slots facilitate render adhesion and aid in minimising distortion in the lintel during the strenuous slot-punching process.

Our Rendabar is proudly made in Coffs Harbour, NSW. Unlike our competitors we are proud to design, manufacture and hot-dip galvanised Rendabar Generation III in Australia in the same facility as our Solid Base Angle and T-Bar in Coffs Harbour, NSW. Rendabar Generation III proudly carries the certified Australian Made and Owned logo on the product label.

Like all Galintel Steel Lintels, Rendabar Generation III is clearly labelled with the Galintel brand and product details including product name, size, length, unit weight and durability classification.

Galintel Rendabar Generation III is also metal stamped before galvanising with the Galintel brand name, the ‘R3’ durability classification and the Australian Standard, AS 2699.3. This allows every genuine Galintel Steel Lintel to be clearly identified after installation which is required by the NCC and AS 2699.3:2020.

Yes. The Rendabar Generation III has undergone render adhesion performance testing through an independent NATA accredited laboratory. Destructive render pull-off adhesion tests have shown that Rendabar Generation III outperforms the previous Galintel Rendabar design for render adhesion. The product has also been tested in a NATA accredited lab for load bearing, with engineering load tables available.

As with all Galintel Steel Lintels, Rendabar Generation III has been manufactured and tested in accordance with Australian Standards. Rendabar Generation III is hot-dip galvanised in accordance with AS/NZS 4680:2006 and has a zinc coating of 600g/m² (85 microns). This achieves the ‘R3’ durability classification as described in AS 2699.3:2020. For identification and traceability, it also complies with the stamping and labelling requirements of AS 2699.3:2020.

Galintel Rendabar Generation III technical data sheets and safe load tables are available to assist engineers in determining this. A qualified design engineer will specify the appropriate size and length for your application.

Galintel stock a wide range of lengths in two sizes for Rendabar Generation III. Like any steel lintel, Rendabar Generation III is not recommended to be cut as this will breach the protective coating. A qualified design engineer can recommend the right size to avoid modifying the length. For projects requiring a significant quantity of custom-sized lintels, Galintel offers manufacturing and delivery services. Please contact our customer support team at 1800 LINTEL to discuss specific project requirements.

Rendabar Generation III has a durability rating of ‘R3’, which makes it suitable for use in a large range of Australian environments. For more information on durability requirements for specific environments refer to AS 2699.3:2020. Note: render adhesion may be adversely affected if any additional coatings are applied over the galvanized coating.

Yes. During installation props must be positioned and not removed until the mortar is cured. Props should be no further apart than 1.2m.

Yes. Lintels are covered in the NCC and in the ABCB Housing Provisions, which contain Deemed-to-Satisfy guidance for acceptable construction to comply with various parts of the NCC, available here.

The Galintel range of hot-dip galvanised steel products including lintels, stair stringers, retaining wall posts and builders’ posts are available to purchase through our authorised resellers, hardware retailers, trade centres, building materials suppliers and distributors.

If you are looking to purchase, please visit our ‘Where to Buy’ page to locate your nearest store.

If you are interested in becoming an authorised stockist, please visit our ‘Resellers’ page for more information.

Our customer support team can be contacted through our website ‘contact’ page or via our national freecall number 1800 LINTEL and can assist with product availability, product information or forward on technical queries to our team. For product specification and selection advice, please engage a qualified design engineer.

Contact Galintel

Got a question about our Rendabar? Get in contact with us using the form below: